- Elastochem

- Insulthane® 450 NM ocSPF

Insulthane® 450 NM

No mix, easy-to-spray, open-cell spray foam insulation

Insulthane® 450 NM is a two component no mix open-cell spray foam insulation that can be applied in a wide range of temperatures making it suitable for a variety of climate conditions. It features consistent high quality performance with easy no mix processing, meaning less downtime and higher jobsite efficiency. Insulthane® 450 NM is designed to provide little to no voiding when applied and has superior self-adhesion. The high-yield formula expands to seal all cracks, voids and gaps to create a custom-fit insulation.

Key Properties

0.53 lb/ft³

Core Density

3.8 at 1”

Aged R-Value (90-Day)

Product highlights

Discover the exceptional features that set our products apart.

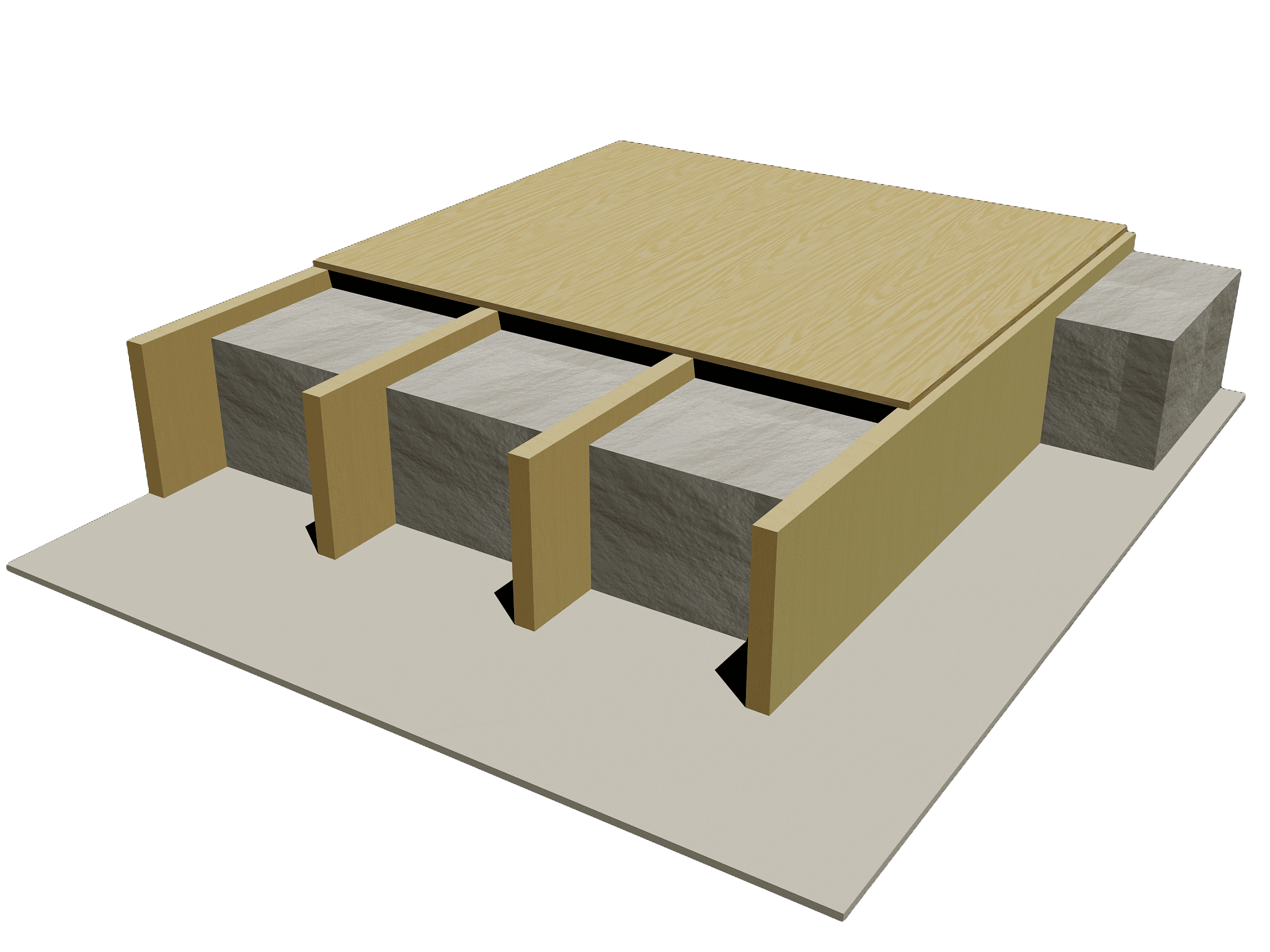

Insulthane® 450 NM

An application of Insulthane® 450 NM in an attic space.

Technical Specifications

View technical information and specifications for Insulthane® 450 NM. For more information, please contact a member of our team.

Core Density

0.53 lb/ft³

Aged R-Value (90-Day)

3.8 at 1”

Open-Cell Content

97%

Dimensional Stability (Volume Change after 28 days)

@ -20ºC, -1.0% @ 80ºC, -7.0% @ 70ºC & 97% ±3%RH, -6.0%

Flame Spread

Flame 405, Smoke 235

Water Vapour Transmission

9.35 US Perms, 535 ng/Pa·s·m²

Fungi Resistance

64.5 psi, pass

Time to Occupancy

25 hours

CCMC

#14444-L

CCRR

CCRR-0396

Global Warming Potential (GWP)

< 1

Related Products