Low Carbon Spray Foam Insulation

RDH Building Science and Toronto Metropolitan University research highlights closed-cell spray polyurethane foam (ccSPF) insulation's role in embodied carbon reduction

READ THE STUDY

The carbon advantage of spray foam insulation

The RDH x TMU study examines how different insulation materials influence embodied carbon in full building assemblies. Its findings show where meaningful reductions can be achieved through smarter material choices and higher-performing systems, with closed-cell spray polyurethane foam (ccSPF) included as a high-efficiency option that can help reduce material use and lower embodied carbon across many assemblies.

embodied carbon

What is embodied carbon?

Embodied carbon refers to the greenhouse gas emissions from manufacturing, transporting and installing building materials. These emissions are locked in at the time of construction, before a building is operational.

Extraction of raw materials

Manufacturing of products

Transportation to site

Installation

End of life

Permanent within building

COMPARING INSULATION

Embodied carbon of common insulation types vs insulation thickness

Both open and closed-cell spray foams show lower embodied carbon per thickness than mineral wool boards and XPS, while still delivering strong thermal performance. Fiberglass and EPS fall lower overall, but vary in effectiveness per unit thickness.

Source: RDH Embodied Carbon – Elastochem / Honeywell Enclosures 2025

Why closed-cell spray foam supports lower embodied carbon

Material Efficiency

Higher R-value per inch means less material is needed to achieve performance targets.

Transportation

Achieves the same coverage as traditional insulation with less material and fewer deliveries.

Installation

A single spray-applied system simplifies installation and minimizes job-site waste.

Total Carbon

Material efficiency across the enclosure helps reduce the overall embodied carbon footprint.

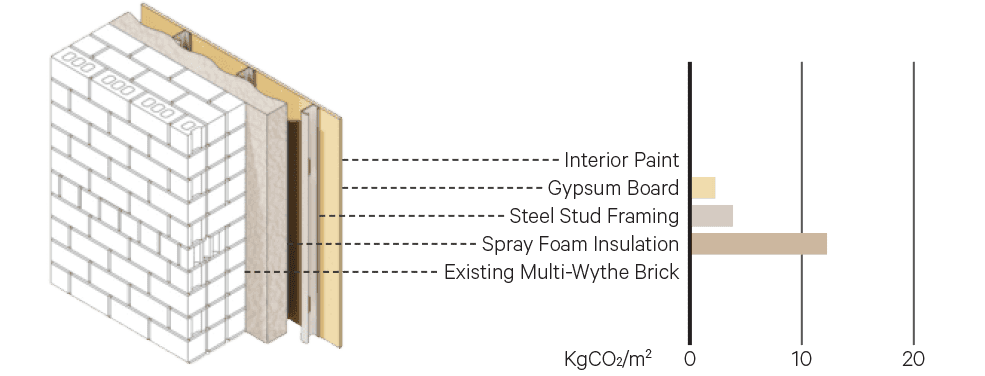

Spray foam compared to mineral wool

Comparing the carbon impact of two retrofit wall assemblies, both designed to achieve R-24

40% Lower Embodied Carbon

The ccSPF assembly showed approximately 40% lower embodied carbon than the mineral wool assembly.

Multiple Control Layers

ccSPF delivers thermal, air, and moisture control in a single material, reducing the need for additional layers.

Consider the Full Assembly

Embodied carbon is influenced not only by insulation but by the full wall assembly and required performance layers.

Source: RDH Embodied Carbon – Elastochem / Honeywell Enclosures 2025

Existing Masonry With Interior Mineral Wool Insulation

|

Phone

|

|

|---|---|

|

Embodied Carbon per m² of Enclosure

|

33.7 kg CO₂/m²

|

|

Effective R-Value of Enclosure

|

R-24 ft²·°F·h/BTU

|

Existing Masonry With Interior Spray Foam Insulation

|

Phone

|

|

|---|---|

|

Embodied Carbon per m² of Enclosure

|

19.2 kg CO₂/m²

|

|

Effective R-Value of Enclosure

|

R-24 ft²·°F·h/BTU

|

TRANSPORTATION IMPACT

Transportation is a carbon driver

Transportation is a major contributor to embodied carbon. Mixed and manufactured onsite from liquid isocyanate and resin components, one truckload of ccSPF can replace roughly five truckloads of board stock insulation. That means fewer deliveries, less fuel burned, lower site congestion, and reduced logistics emissions.

1 Truckload: Spray Foam

5 Truckloads: Board Stock

Calculation based on 53-ft transport truck carrying ~40 sets of ccSPF (≈4,500 bdft per set, ~180,000 bdft per truck) compared to 1 truckload of board stock at ~35,000 bdft.

SUSTAINABLE PERFORMANCE

Lower environmental impact with ccSPF

Thermal, Air and Vapour Barrier

One application delivers a system of thermal performance, airtightness and vapour protection

Low-GWP Chemistry

Formulated with HFO blowing agents that significantly lower Global Warming impact

Recycled Content

Insulthane Extreme ccSPF can repurpose ~6,000 plastic bottles in the average home.

Fewer Truckloads

Spray-application and integrated material reduces delivery volumes and fuel consumption

Thermal Performance

Highest R-Value per inch compared to traditional fiberglass and boardstock materials

Lower Carbon from the Start

Embodied carbon reductions begin long before the building is occupied.

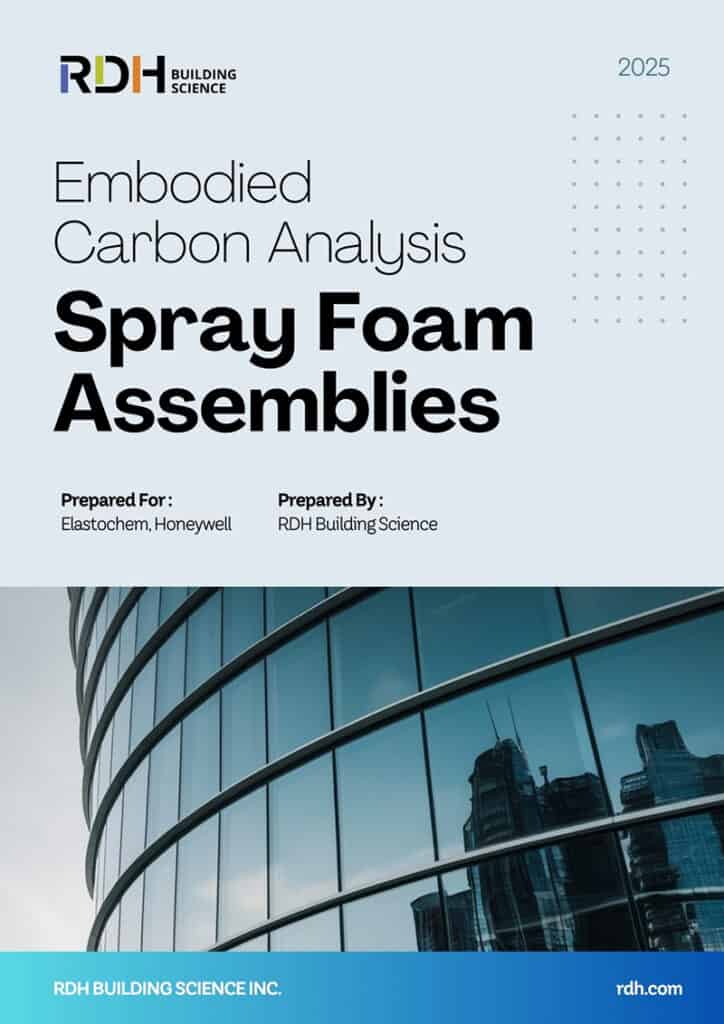

REPORT

Embodied Carbon Analysis for Spray Foam Wall Assemblies

About the report

Prepared by RDH Building Science for Elastochem and Honeywell, this study compares Canadian and U.S. exterior wall assemblies using open and closed-cell spray foam and other common insulation types, outlining embodied carbon results by assembly and life-cycle stage.

Get the Embodied Carbon Report

LOW CARBON SPRAY FOAM

Choose Insulthane® Extreme for low carbon enclosures

Insulthane® Extreme closed-cell spray foam helps reduce material use, transportation demands, and installation waste to support lower environmental impact from day one.

Join us for a Lunch & Learn

Join us for a Lunch & Learn covering embodied carbon, spray foam insulation, and smarter enclosure design choices.